Manufacturers are well aware of the value of data and the need for digitizing their operations. But selecting and testing solutions typically requires a major investment of time and resources, making it prohibitive to find, test, and deploy solutions without major risk. Admittedly, there are many, many challenges when it comes to deploying technology.

Below are some of the core challenges we hear from customers:

- Cost of Implementation: Testing out solutions in time-intensive pilots often leads to upfront expenses, months and months of internal investment, and no clear proof that the solution is actually going to deliver. They need a way to test with minimal time and cost.

- Risk of Failure: IoT deployments have high failure rates, and manufacturers are weary of deploying another “digital transformation” tool that positions itself as a silver bullet, but leaves them high and dry. They need to eliminate the risk of failure.

- Definition of Success: Mapping out what a solution can actually deliver (both today and five years from now) is an important commitment from both the manufacturers and the vendor, ensuring that they do not land in pilot purgatory. Both parties need to outline a measure of success and a timeline for accomplishing it.

The MachineMetrics Free Trial program takes these challenges head-on, offering a program to help users get started quickly without the cost and risk.

Deploy Analytics with Ease

Real-time, accurate production data is changing our customers' businesses. With MachineMetrics, there is finally a source of truth to rely on day in and day out. We provide the tools to take action on key insights within the data, enabling use cases at the machine, plant, and enterprise level.

And we can prove it in a free trial:

It's Free – Really

Unlike many pilot programs, the MachineMetrics trial is actually free. Some trials come with hidden costs, limited functionality, and time-bound constraints.

This trial is not just an offer but a statement, a testament to our confidence in our product and our commitment to your success. It presents you with an opportunity to see for yourself the value that MachineMetrics can deliver, and the speed at which you can begin to realize that value.

Minimal Input, Maximum Output

We know your time is valuable - and we do not say that lightly. MachineMetrics is designed for a simple setup process with out-of-the-box capabilities. Your team won't need to spend time on custom development or complex configuration. Put simply, you don’t have to be a data scientist or a software engineer to use MachineMetrics.

No Risk

The MachineMetrics free trial provides a risk-free environment for you to test out automated production monitoring and analytics. You don't need to worry about the financial risk or the productivity risk of a steep learning curve for your staff. We work with you to ensure the trial process is smooth, so you can focus on experiencing the benefits.

Prove Value Before Scaling

Have a challenge or use case in mind? Leverage our trial program to prove that we can solve your problem and unlock valuable insights with your production data.

- Custom equipment or legacy machines? We can connect to old and new machinery, of all makes and models, at rapid speed.

- Need automated, accurate data? Our automated data collection capabilities reduce the load on operators and ensure that your production data is both real-time and accurate.

- Unlocking actionable insights? MachineMetrics pinpoints your biggest problems and highlights the opportunities that your team should focus on at the machine, plant, and enterprise level.

Setting Expectations

Despite the support and technology we bring to the table, ultimately it's the effort of both our teams to get started on the right path to run a successful trial. Here are a few items to consider to make sure you are ready and committed for the program:

Qualifications:

- 25+ machines in your facility

- Cloud/SaaS not a problem

- A champion to drive the project

- Executive team buy-in

- Timeline of deployment

- Use case(s) identified

Don’t meet all the criteria? No problem, talk to our team about other ways we can we can work together.

Internal Time and Resources:

Roughly, we break the trial down into four distinct stages which require varying degrees of input from your internal resources, incuding a project champion, IT contact, and an executive sponsor.

Many trial experiences require a lot of time, resources, and energy, with no goal or end in sight. Ours was designed to allow you to not only experience MachineMetrics but to unlock value very quickly.

In fact, we've been able to streamline our trial process in such a way that it only requires a day and a half of total time invested on the manufacturers' side. This keeps your investment in time, staff, and internal resources to a minimum.

Optimizing Your Trial Experience

How can you guarantee the success of your trial? There are two critical components that you should address:

- Involving Executives: High-level buy-in is crucial. Not only does it ensure that the necessary resources and support are dedicated to the trial, but it also vests your leadership team in the trial's success.

- Defining Clear KPIs: Every company has unique use cases and Key Performance Indicators (KPIs). It's essential to identify your KPIs before starting the trial. It helps you clearly measure the impact of MachineMetrics on your operations.

Recognizing Success

We need to be very careful when approaching trial engagements. Often the cause of failed IoT initiatives is a lack of alignment around what “success” actually means.

As mentioned above, this is why it is incredibly important to identify the use cases and KPIs that will be pursued/measured for the free trial.

Below are some core examples of what “success” often looks like, but there is also a chance that you are looking to pursue other use cases, which we would be happy to discuss.

Ease of Implementation

Our user-friendly guides and solution delivery managers ensure a smooth and quick implementation process. You'll have the system up and running in quickly, often without the need for any onsite support.

Improved Utilization

Say goodbye to spreadsheets. With MachineMetrics, you will have real-time, accurate utilization data. This is a core use case that may customers start with, giving them visibility into the actual performance of their operations and allowing them to establish a benchmark to improve upon.

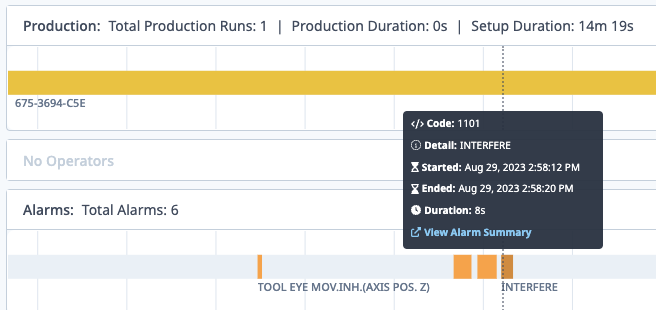

Actionable Insights

Our software doesn't just offer data; it provides actionable insights that help you make decisions faster. You can uncover trends in downtime, identify process bottlenecks, spot problem machines, and so much more. No need for advanced analysis skills – we make it as straightforward and actionable as possible.

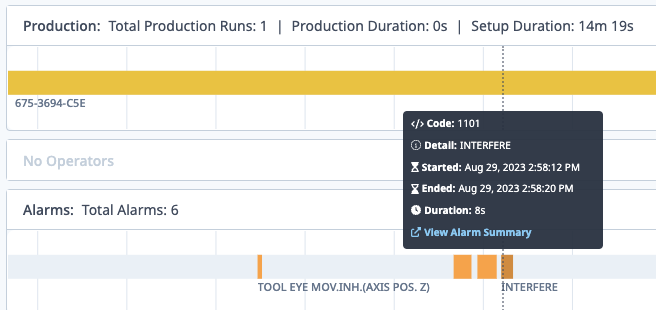

Diagnostic Data

MachineMetrics does more than just highlight equipment reliability issues. It provides in-depth diagnostic data that can help you prevent future downtime. These diagnostics help staff, from operators to maintenance techs, learn the "why" behind issues so they can improve maintenance programs.

Post-Trial: Unlocking the Value of Scale

Approaching the end of a trial comes with the prospect of scalability and the pursuit of advanced use cases.

While a free trial offers the opportunity to prove the value of the solution in a limited capacity, MachineMetrics was built to scale, supporting use cases at the machine, plant, and enterprise level.

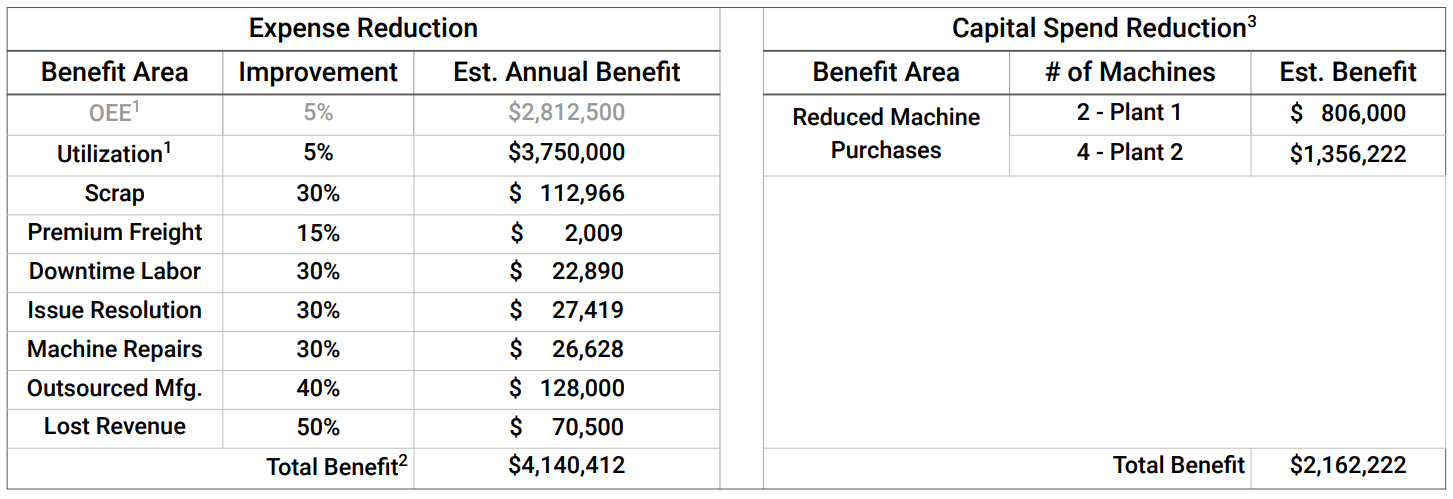

Results Across a Larger Machine Set

With the MachineMetrics system implemented, you will notice patterns, trends, and a baseline of performance across your machine set. Trends can lead to a better understanding of individual machine performance and the ability to analyze metrics across several dimensions, including machines, operators, groups, shifts, operations, etc.

By connecting your other equipment, this ability to analyze and deliver insights will be multiplied dramatically. For example, we will be able to help you identify performance outliers that are the true cause of major inefficiencies.

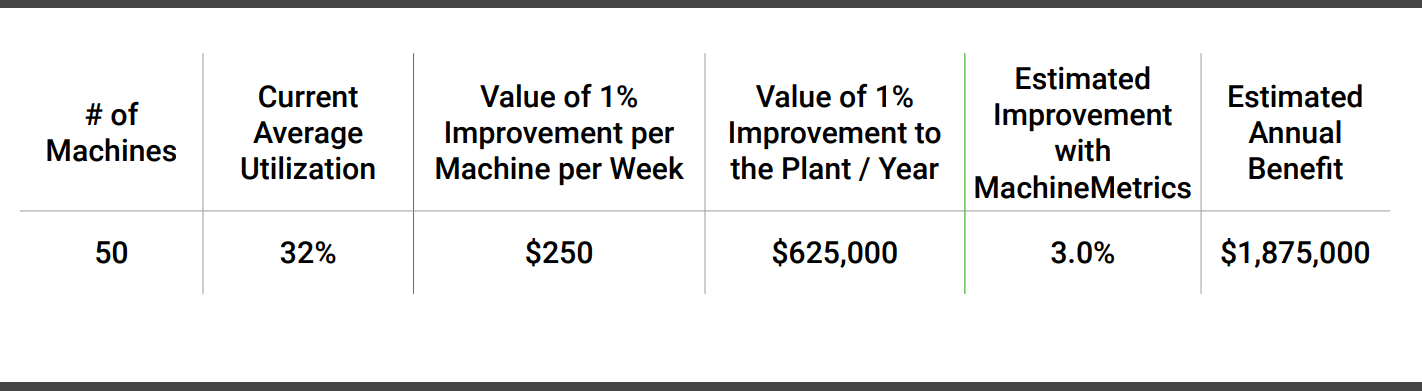

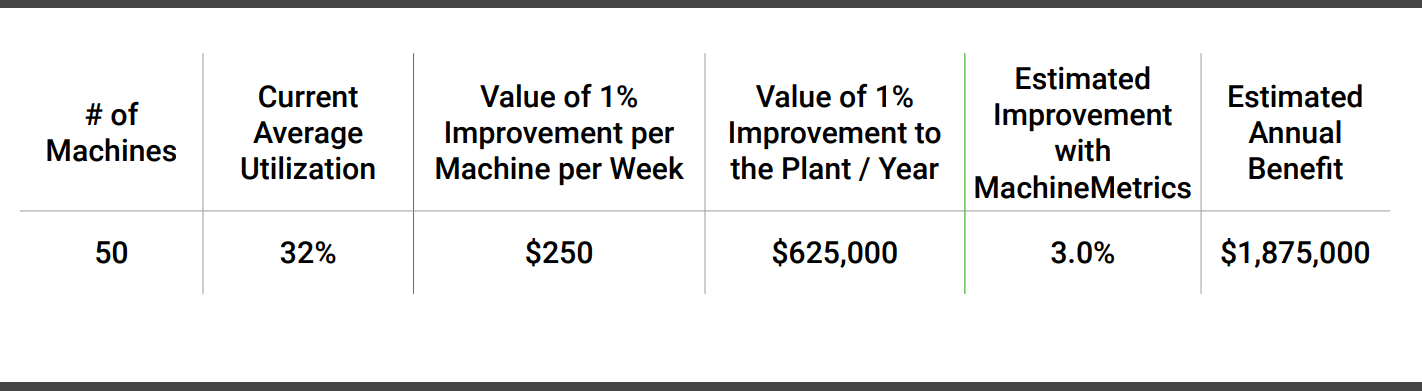

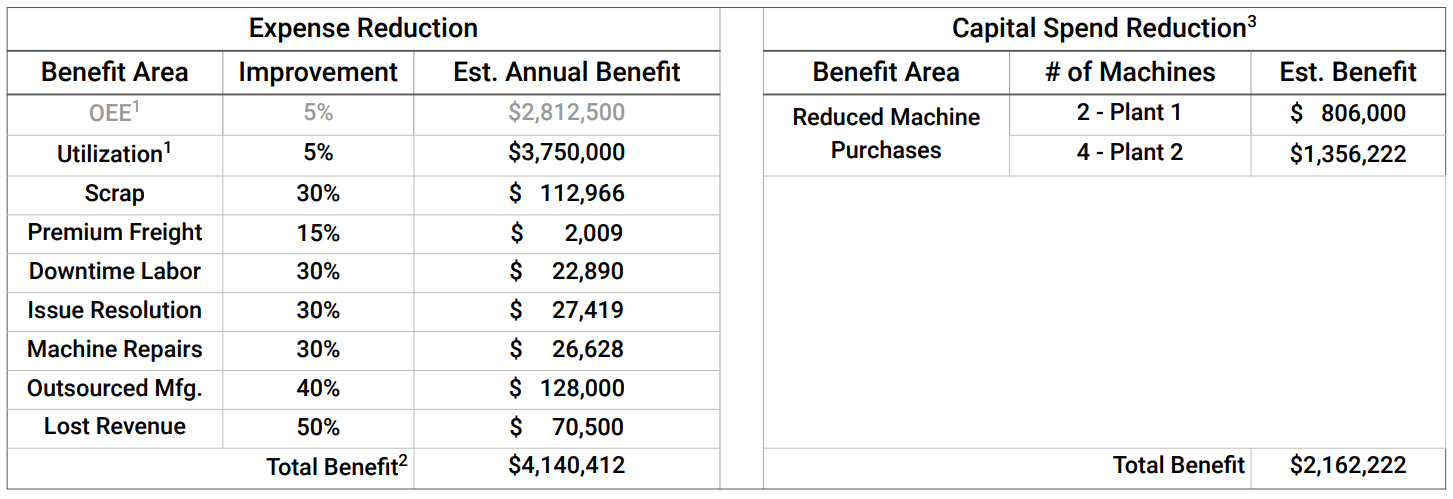

Impact on ROI

With a measure of performance across a small set of machines, ROI can be calculated across your entire fleet. This will help to create a complete picture of the expected value delivered by MachineMetrics when fully deployed.

For example, what does a 5-10% increase in utilization mean from a business perspective?

With trial data in hand, users can build estimates that are based on accurate data.

Getting Started Today

Value, timeline, use cases, buy-in…

There is a lot to consider when deploying solutions to digitize the operation. We understand that and have worked with hundreds of customers to successfully connect thousands of machines. The insights we are driving for these users on a daily basis is incredibly valuable to their operations. It gives us a sense of purpose and a deep confidence in our platform and internal team.

Our free trial program is a testament to the value we can deliver for you. We’ve been able to remove the barriers associated with a test run: eliminating the cost, slashing the investment of time required, and helping give users a proven roadmap to success.

Ultimately, there is one more cost for you to consider: Opportunity Cost. For the manufacturers that fail to innovate and adopt data-driven methodologies, their competitors will take market share.

Although it may appear conservative or safe to continue managing the operation in a traditional way, modern manufacturing relies on real-time, accurate data to make more effective decisions and automate activites.

Production has long since been behind, but for the manufacturers that are taking advantage, there will be a major cost for their industry associates who do not move quickly enough.

What’s holding you back from trialing the platform?

Plug-and-play Machine Connectivity

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments