Key Takeaways:

- MachineMetrics is introducing new features and tools designed to improve machine performance monitoring and operational efficiency.

- These 2024 releases focus on expanding data accessibility and enhancing user experience for manufacturing clients.

- Key innovations include enhanced predictive maintenance tools, real-time analytics, and greater integration options with factory systems.

In a recent webinar led by Rutherford Wilson, Chief Product Officer at MachineMetrics, attendees were given an exclusive preview of the features set to be released in 2024.

While some of these capabilities remain in development, others are currently rolled out at customer sites as betas. (If you are interested in testing any of the below features, please get in touch with our team!)

We’re excited to continue reshaping the production intelligence space in 2024 with a number of advanced capabilities to further enhance decision-making, automate production, and optimize operations.

Below is a summary of the features covered in the webinar, but you can access the complete recording here.

Custom Dashboards: Your Data, Your Dashboard

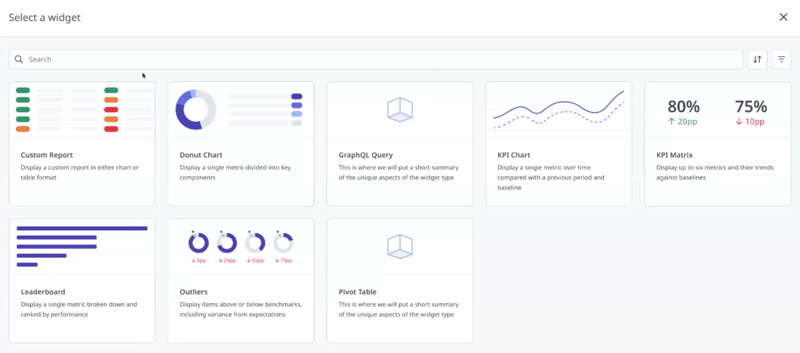

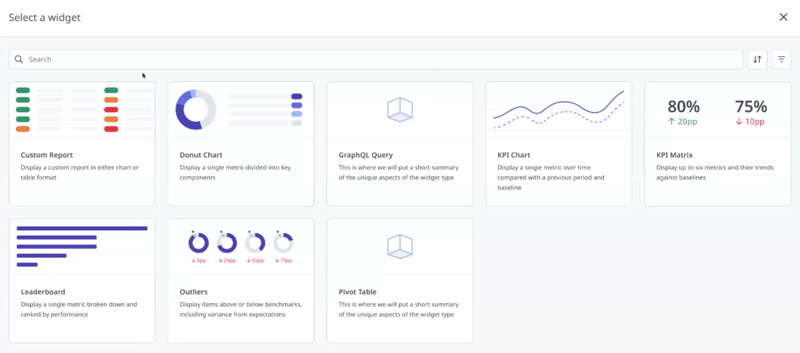

A natural extension of the company dashboard, the new custom dashboard feature will allow teams to visualize data specific to their team’s needs. Users will be able to create as many custom dashboards as needed to support their ongoing processes and reporting requirements.

Bonus: We’re also planning to offer a pivot table widget for more advanced data analysis, including calculated fields and the ability to graph the information.

Scheduled Reports: Find It In Your Inbox

Scheduled reports automate the regular delivery of reports and dashboards straight to your inbox, facilitating informed decisions without any need to log into the system. This can be especially helpful for managers and executives who want a summary of performance information on a regular basis.

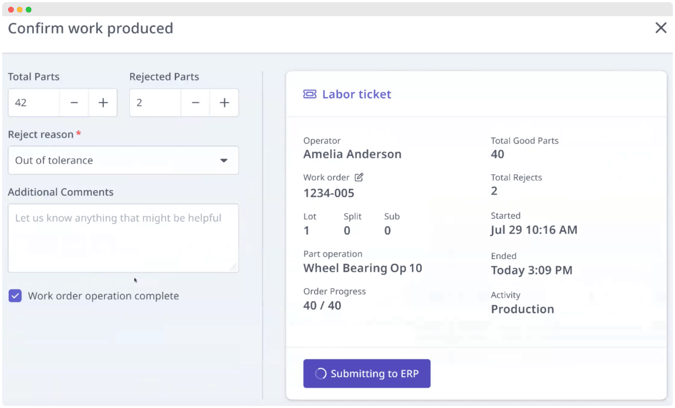

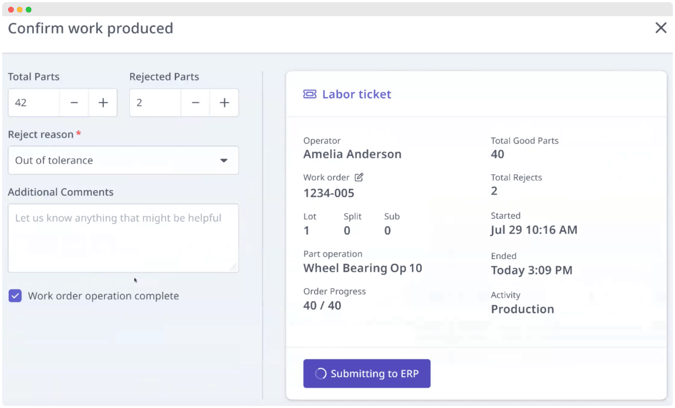

Job Tracking with Labor Ticket Entry

With the new job tracking capabilities, users will have one system to track work, capture downtime events, record scrap, and submit labor to the ERP.

By tying ERP information to MachineMetrics, users can eliminate manual data entry, streamline operations, and provide real-time job progress updates.

What’s also powerful? Combining this capability with production scheduling…

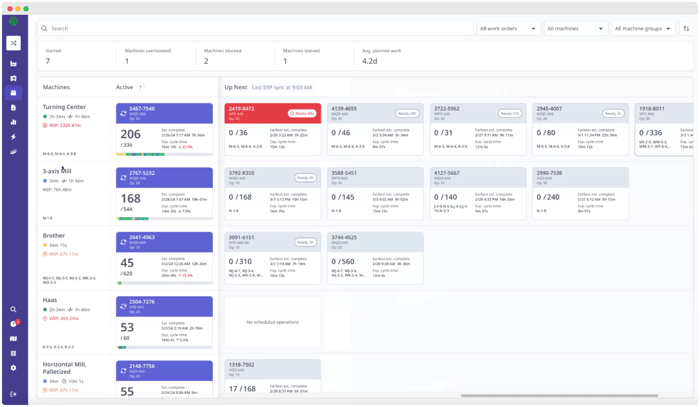

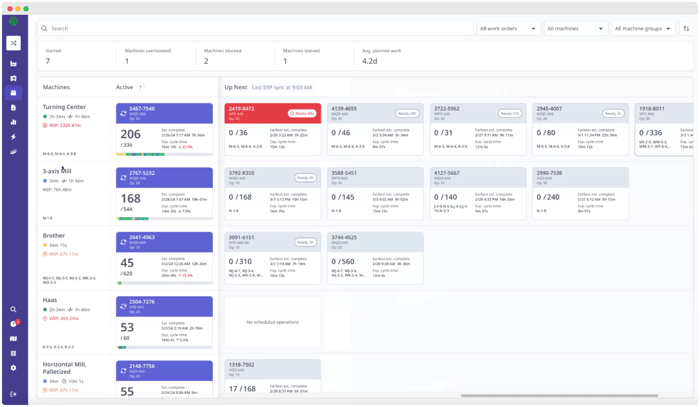

Production Scheduling: Accurate and Dynamic

How do you schedule work given all the variables that must be accounted for?

It’s an incredibly challenging task. Usually, managers are in Excel working off of estimates or averages to understand what work can be accomplished within a given time frame - and then a downtime occurs or a new order comes in - and the schedule is entirely thrown out of order.

MachineMetrics is bringing accurate data to the table to help scheduling managers plan better schedules and react faster than ever. Predictive logic will determine when a job is going to be complete and recalculates automatically when unplanned downtime occurs.

Will your work be completed on time? You’ll know.

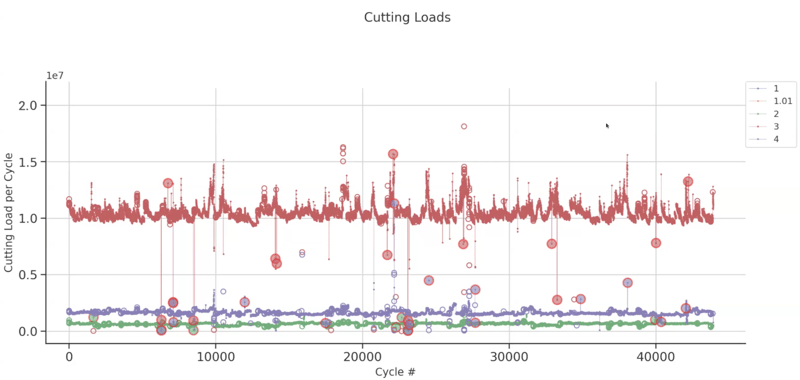

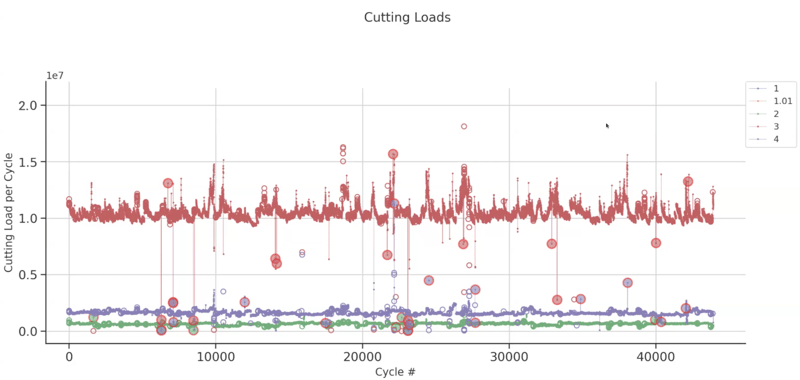

Tool Anomaly Detection

For Fanuc Focas controllers, data can be pulled from the control at a high frequency, enabling MachineMetrics to identify anomalies that suggest a tool chip or break - and then notify you immediately.

The user can then confirm a tool failure has occurred. As this data is compiled, you can take the next step of initiating an E-stop directly when the feature senses that a tool failure is imminent.

The goal with this feature is to minimize downtime and scrap, while maximizing the life of your tooling.

The Year Ahead

There are several major updates ahead and we're excited to be unveiling many of the capabilities that will enable manufacturers to bridge the gap between their business and operational systems.

If you are a MachineMetrics customer, please feel free to reach out and inquire about these upcoming capabilities.

In the case that you are not a customer, but would like to learn more, feel free to set up time with our team or watch the full webinar recording.

Plug-and-play Machine Connectivity

.png?width=1960&height=1300&name=01_comp_Downtime-%26-Quality_laptop%20(1).png)

Comments