Transform your approach to maintenance with MachineMetrics' bearing monitoring system. Deploy in minutes to harness the power of machine data to keep your equipment running longer and healthier.

Calendar-based preventative maintenance plans are not only inefficient but often lead to over-maintenance, which is expensive, or under-maintenance, which results in machine breakages and downtime.

Monitor real-time bearing conditions such as vibration and temperature to identify bearing brinelling, flooding/lack of lubricants, and when failure is about to occur.

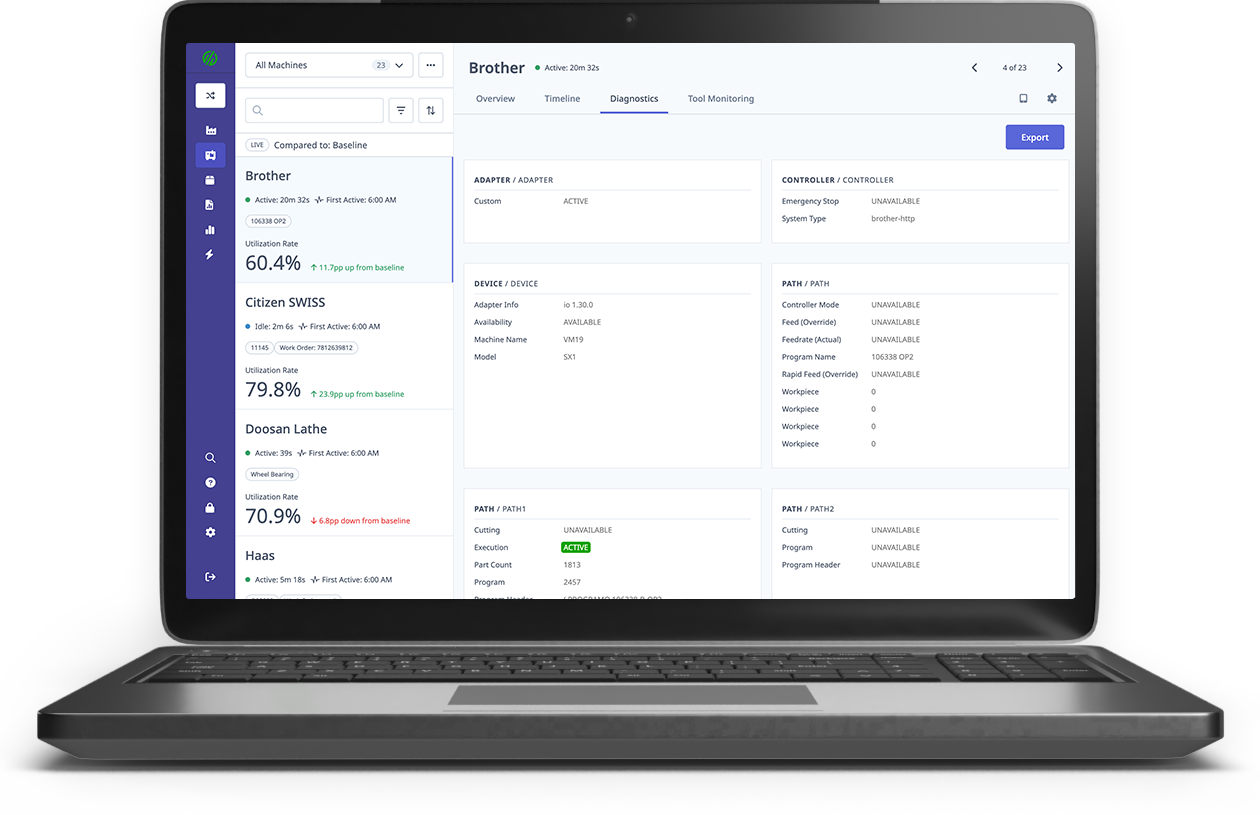

Connect to any asset by connecting the MachineMetrics Edge to the ethernet port of the control and/or sensors. Software on the edge processes data from the machine in real-time and streams the data securely to the MachineMetrics cloud for instant visibility into machine conditions.

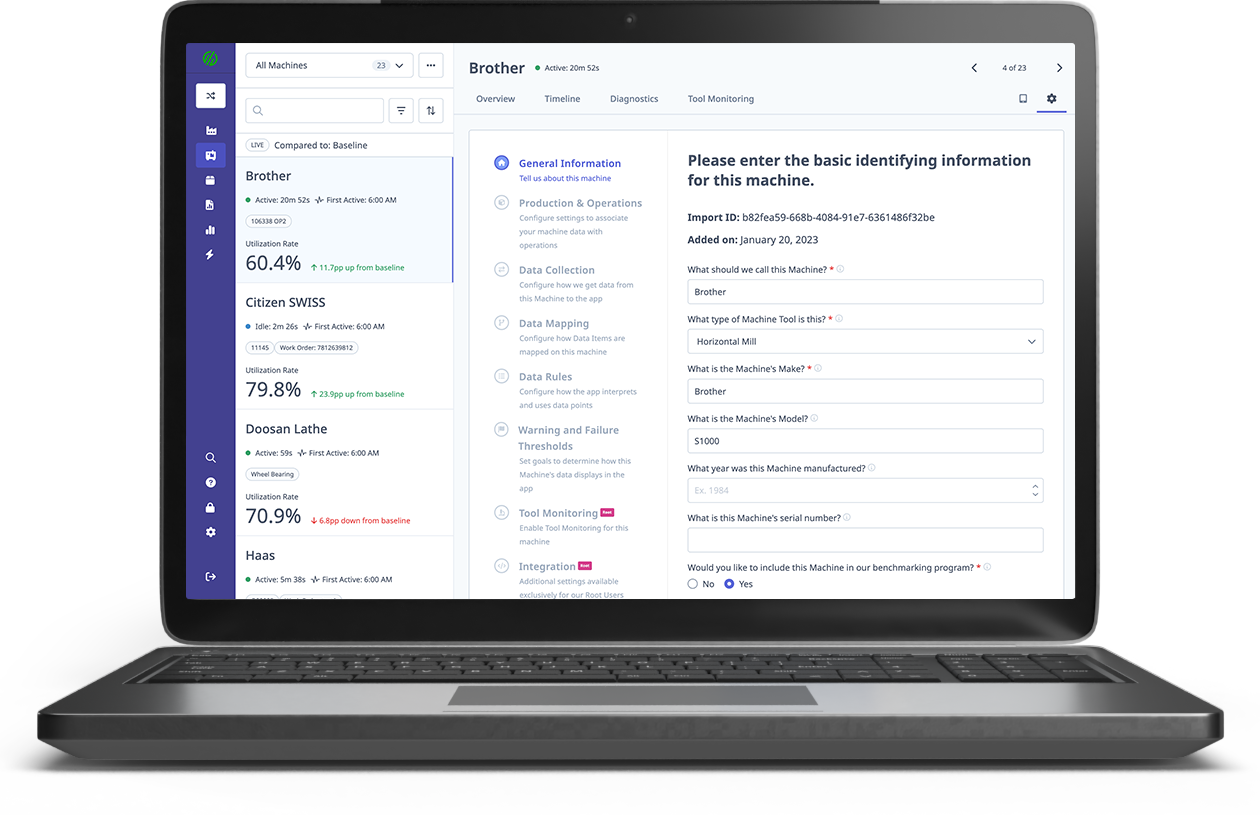

Automatically map out, collect, and standardize available data points like Internal Sensors, Machine Status, Modes, Alarms, Overrides, Load, Speeds, Feeds, and more.

Add external sensors or connect older equipment with digital and analog IO that can be configured and managed remotely through web interface.

Automated capture and transformation, or contextualization, of machine data enables consumable machine data and insights in a matter of minutes.

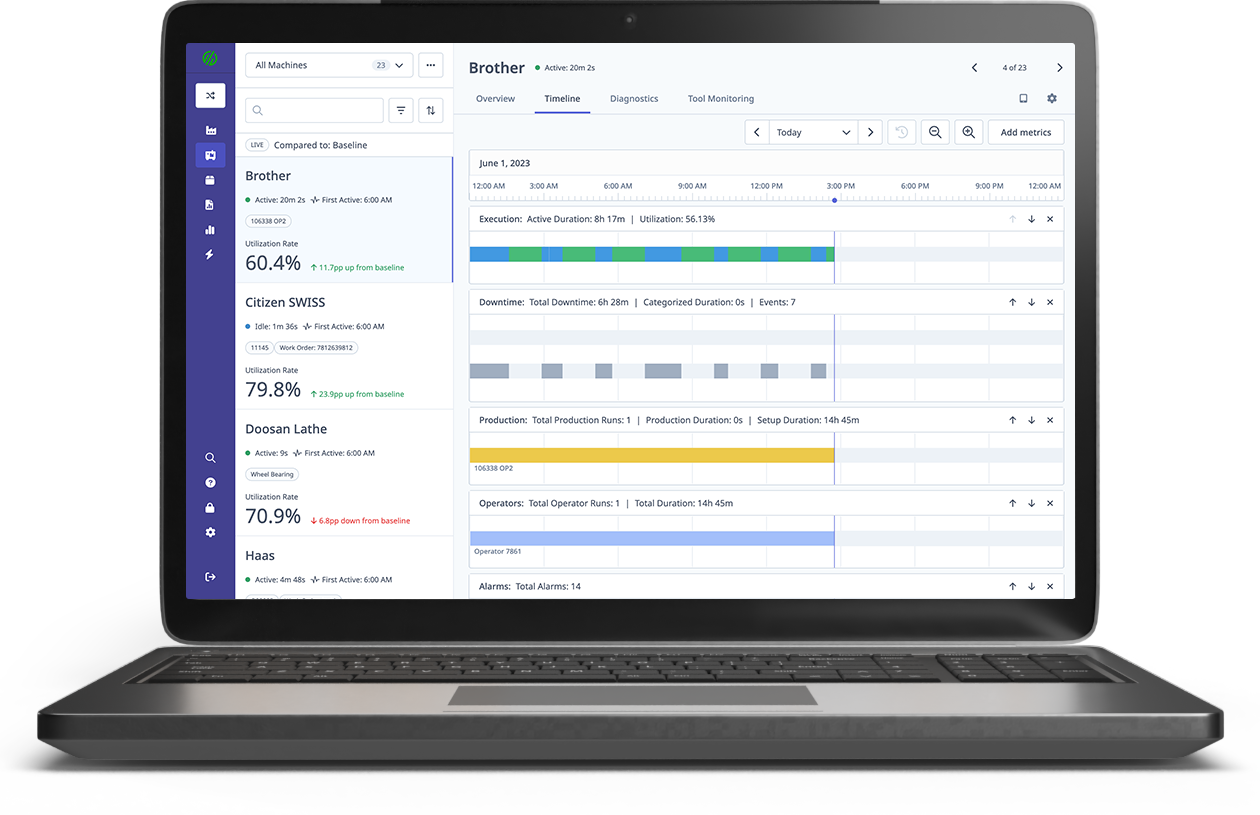

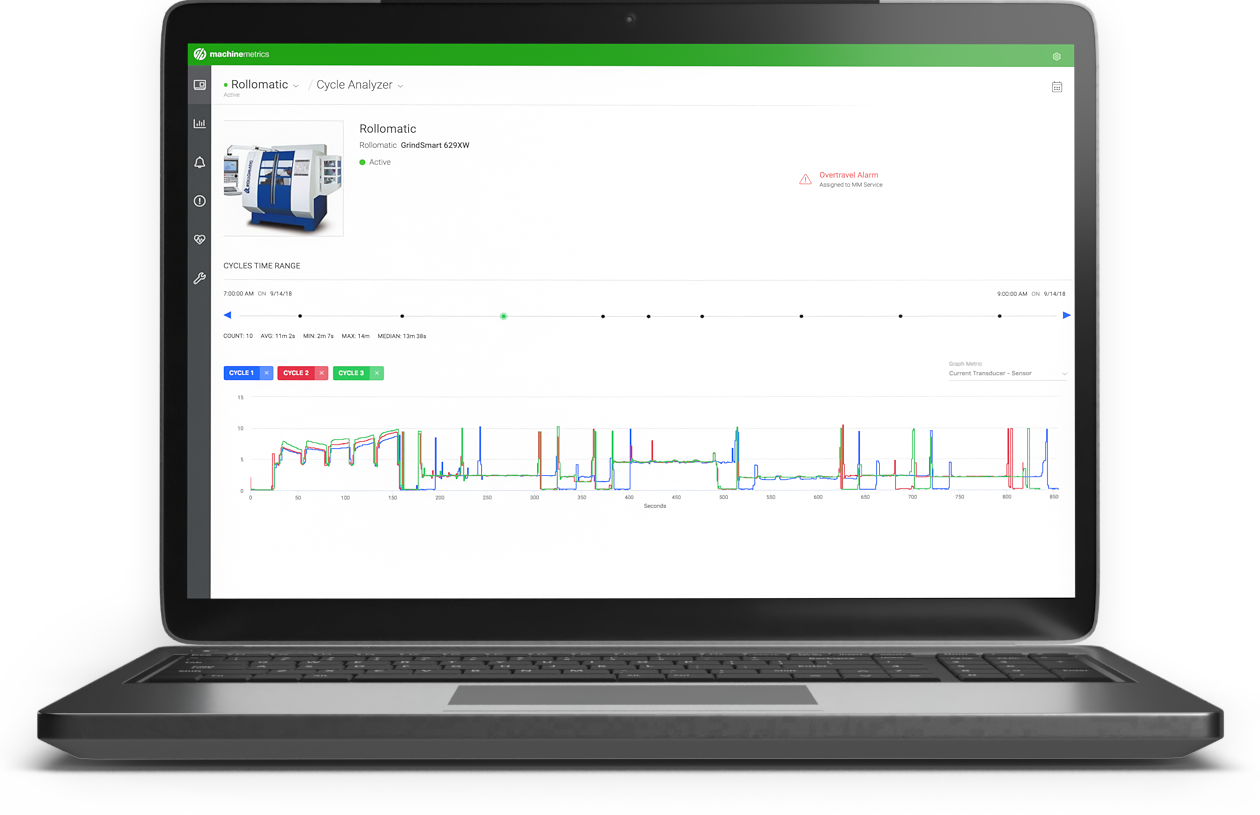

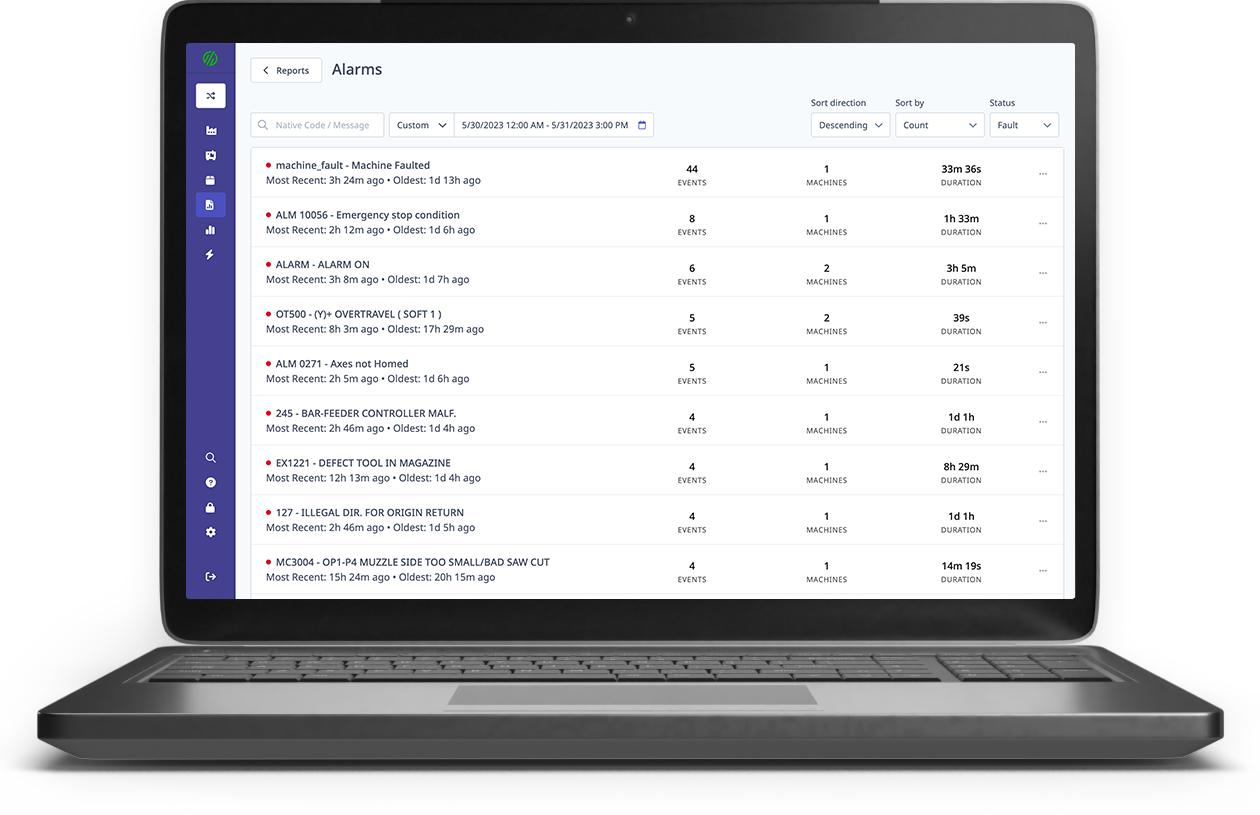

Analyze machine control and sensor data to avoid unplanned downtime. Display this data in real-time to monitor bearing condition and predict failure. View and export real-time machine data and alarms as time-series data and charts to help diagnose and resolve problems

View and manage the status and health of your CNC machine bearings; export real-time machine data and alarms as time-series data and charts to help diagnose and resolve problems.

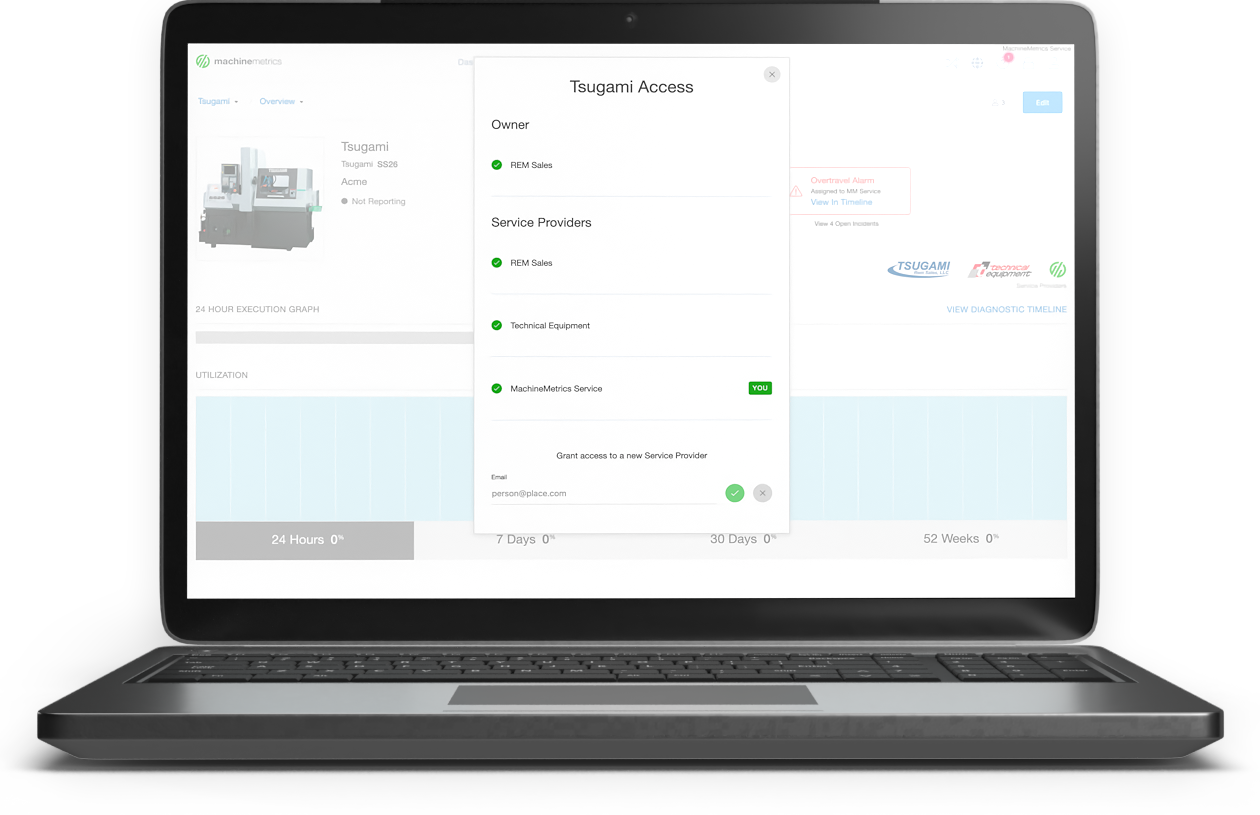

Instantly share machine data with your service provider so they can provide remote service to fix bearing wear.

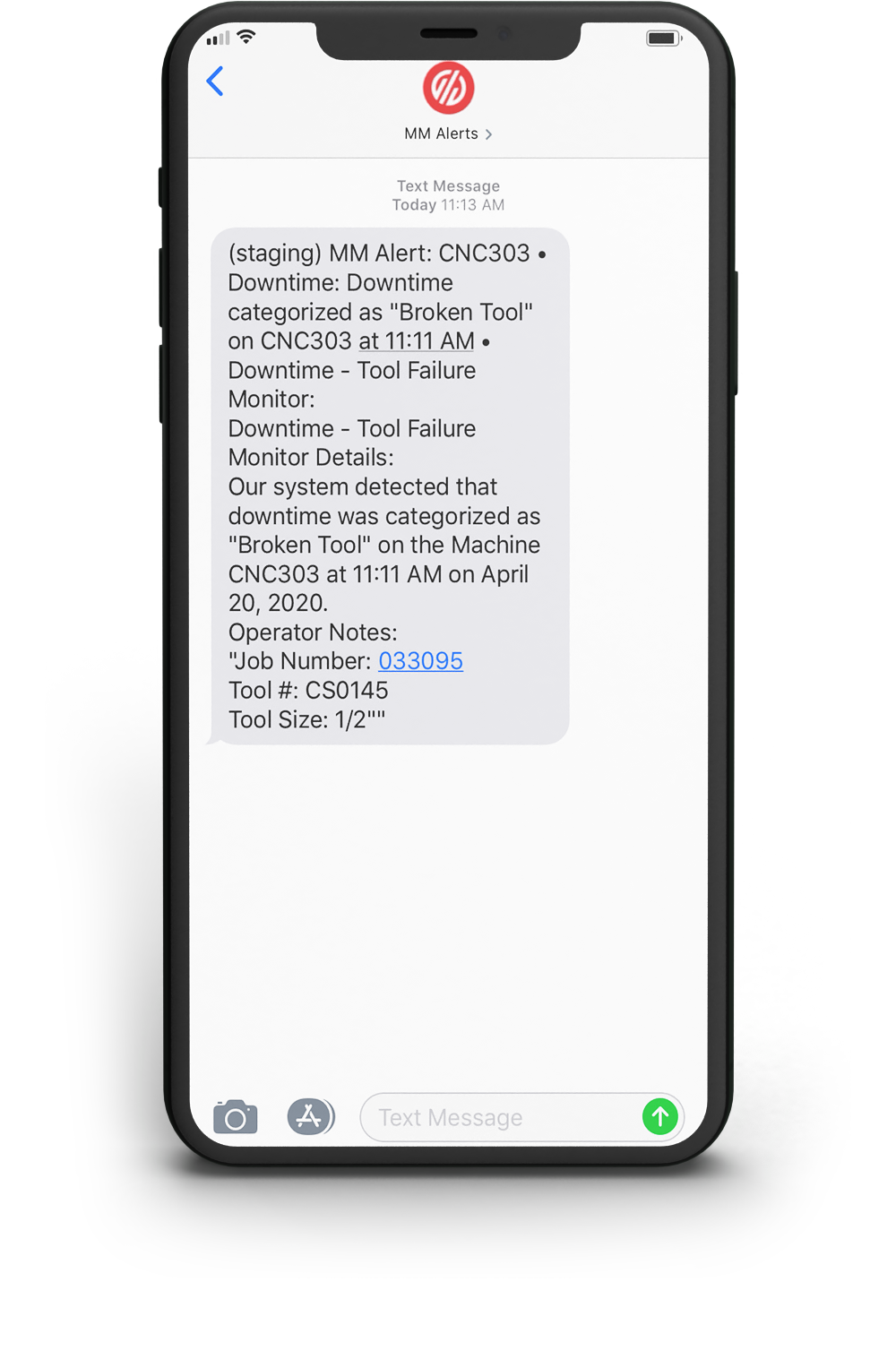

Enable predictive maintenance by alerting the right person at the right time when action needs to be taken. Track incidents through a workflow with reassignment, resolution, and full audit tracking

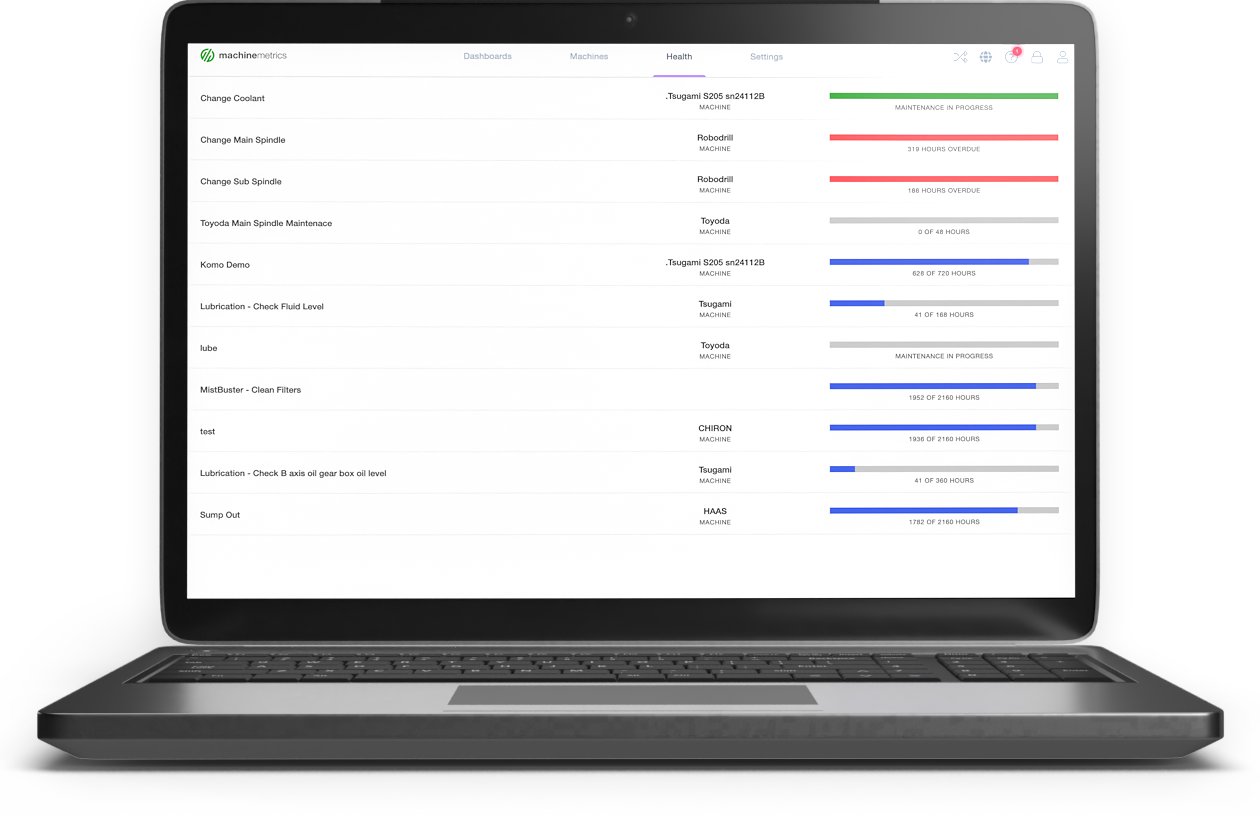

Tailor preventative maintenance schedules to the demands of usage in your operations. Collect and analyze the data necessary for diagnostic and predictive maintenance.

Identify what alarms are causing the most amount of downtime with full alarm histories for each machine, and a summary of alarms across your entire shop floor.

Create and manage preventative maintenance schedules that are tied to calendar time, usage time, or initiated from machine condition limits.

Supercharge your predictive analytics applications with high-frequency machine data to diagnose and predict and avoid various types of failures on your manufacturing equipment.

Join hundreds of Manufacturing organizations across the globe that use MachineMetrics software to collect, monitor, analyze, and take action on their manufacturing equipment data.

Book a tailored demonstration of MachineMetrics that aligns with your specific manufacturing needs.

Book A Demo NowEasthampton Office

116 Pleasant St, Suite 316, Easthampton, MA 01027